PRODUCTS

Tel:+86-139 5883 9733

E-mail:hy@hgpacker.com

Product details description

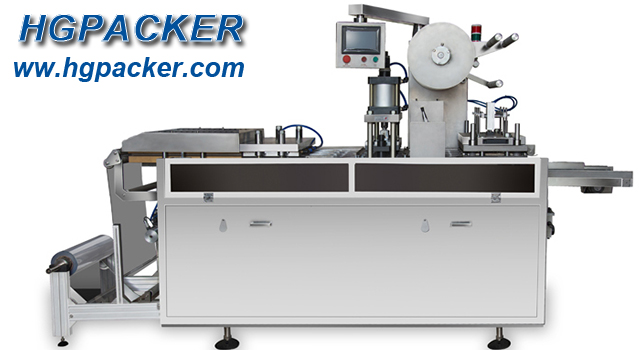

Introduction:

This machine adopts a fully automatic flow covering blow moldings or plastic sucking moldings, punching

and die cutting as the special properties of product requires of the users. It is with advanced technology,

safe and simple operation, which will avoid the consumption of labor on the manual punching and

contamination from the touch with the employee. therefore, the quality requirement is secured during

the production. Aligned heating is employed by the equipment, and it enjoys low power consumption,

small covering of land.

It is applicable to the plastic ware such as PVC, PET, PETG, PS medicine trays ,

and lids thermoforming boxes.

Performance features:

1. Speed reducer, main-rotating connection, main shaft are on line (to decrease driving error)

for mechanical transmission.

2. Sensor controls are adopted in pneumatic system. PLC control makes the whole machine run

smoothly, keeps synchronous stability during the products are to be packed in multi-labor, long-distance.

3. Frequency control of motor speed, servo motor traction, stroke adjustable, stable running,

easy to change mould.

4. Positive pressure formation in the equipment (Puffing forming)

Performance technical parameters:

Model | HG-500S |

Working speed | 15~35cycles/min |

Max.forming area | 470X290MM |

Max. forming depth | 47mm |

distance of feeding | 60--300mm |

air pressure | 0.6-0.8MPA |

cooling water | recycle water 60L/Hour ,for cooling forming mould |

suitable material | PS, PET ,PVC ,HIPS |

Material thickness | 0.15--0.6mm |

total power | 11.5kw,380V |

Dimension: L*W*H | 3500X1000X1800MM |

Weight | 2400kgs |